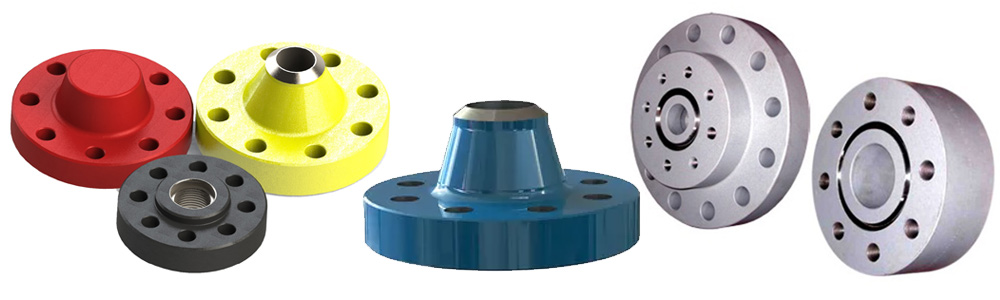

API 6A/6B Flanges

India’s Leading 3000psi 6A/6B Blind Flange, 2000psi 6B Weld Neck Flange, 3000psi 6A Blind Flange, 5000psi 6BX BL Flange, API 6A/6B High Pressure Steel Flange Manufacturer & Supplier in India.

Kanak Steel & Engg Co. is an eminent manufacturing, exporting, supplying, trading and distributing unit of API 6A Flanges / API 6B Flanges, which are used to clean off the ends of piping, valves and stress vessel openings.

They are again and again utilized by manner in their maximum enormous benefit, that is it is able to be used for unanticipated conditions and in very plenty impulsive areas wherein welding is hazardous. Duplex Steel API 6A Flanges are through and big utilized in commercial vessels and on electricity plants, due to their noteworthy benefits. They are to be had in all stress lessons and provide an incredible replacement to attach one-of-a-kind pipe sizes. Available in one-of-a-kind configuration, they’re quite plenty appropriate to attach pipe and tubing parts.

It additionally gives more than a few benefits which includes durability, reliability and near tolerances. The most important feature of flange is to offer a get entry to a pipe line for metering of drinks or gases. Alloy Steel API 6B Flanges is packed collectively among a pair of flanges whilst its miles being established in a pipe line and the whole assembly is known as an orifice flange blending. They are used instead of the usual pipe flanges whilst glide nozzle or orifice plate is being used. It is a skinny plate (normally disk-shaped) with a hole (normally within the middle) this is usually used to distribute the burden of a threaded fastener, which includes a screw or nut.

It is a couple of interlocking discs, created from steel or plastic, typically utilized in vicinity of buttons to lock apparel and for comparable purposes. Different kinds of snaps may be connected to material or leather-based through riveting with a punch and die set unique to the kind of rivet snaps used (putting the punch with a hammer to splay the tail), sewing, or plying with unique snap pliers. Inconel Alloy API 6B Flanges is normally fabricated from steel, and characterized through a helical ridge, called a male thread (outside thread) or simply thread, wrapped round a cylinder.

Largest Manufacturer & Supplier of API 6A 5000 Flange / API 10000 Flange Dimensions, API 6A/6B Blind Flanges Pressure, API 6A Weld Neck Flanges Supplier, API 6A/6B Flanges in Mumbai, India.

Specification Of API 6A/6B Flanges

| Specifications | API 6A/6B Flanges |

|---|---|

| API 6A/6B Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Main Types | Forged / Threaded / Screwed / Plate |

| API 6A/6B Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Production technique | Forged, Heat treated and machined |

| Special design |

As per your drawing AS, ANSI, BS, DIN and JIS JIS Threaded Flange, Socketweld Flange, Slip-On Flange, Blind Flange, Weld Neck Flange |

| Specialized manufacturer of | DIN 2566 en 1092 1 Pn16 Flange DIN 2566 pn16 Rtj Flange API 6A/6B Sorf Flange API 6A/6B Table Flanges DIN 2566 pn10 API 6A/6B Large Diameter Flange API 6A/6B Threaded Flanges API 6A/6B Blind Flanges API 6A/6B Plate Flanges API 6A/6B Weld Neck Flanges API 6A/6B Loose Flanges API 6A/6B Orifice Flanges API 6A/6B Slip-On Flanges API 6A/6B Lap Joint Flanges API Socketweld Flanges |

| Test | Hydrostatic testing machine, Direct-reading Spectrograph,UI trasonic flaw detector, X-ray detector, Magnetic particle detector |

| Equipment | Bending machine, Press machine, electric bevelling machine, Pushing Machine, Sand-blasting machine etc |

| Origin | West Europe /Indian / USA / Japan / Korean |

| Key markets and industries for API 6A/6B Flange | Nuclear power (mostly seamless). Heavy oil refineries. Bitumen upgraders. Petrochemicals and acids. |

| Export to | Indonesia, Ireland, Ukraine, Singapore,Saudi Arabia,Canada, Peru, Dubai, Brazil, Iran, Korea, USA, India, Egypt, Thailand, Spain, Oman etc |

| API 6A/6B Flanges Application | To Connect Pipe & Tubes in Power, Petroleum,Construction, Chemical, Gas, Shipbuilding,Metallurgy, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

API 6A/6B Flange Size & Working Pressure

| Flange Size | Working Pressure (PSI) | Outside Diameter | Number of Bolt Holes | Diameter of Bolt Holes | Length of Bolts | API Ring Gasket |

|---|---|---|---|---|---|---|

| 1-13/16″ | 10,000 | 7-3/8″ | 8 | 3/4″ | 5-1/4″ | BX-151 |

| 1-13/16″ | 15,000 | 8-3/16″ | 8 | 7/8″ | 6″ | BX-151 |

| 1-13/16″ | 20,000 | 10-1/8″ | 8 | 1″ | 7-3/4″ | BX-151 |

| 2-1/16″ | 2,000 | 6-1/2″ | 8 | 5/8″ | 5/8″ | R-23 |

| 2-1/16″ | 3,000/5,000 | 8-1/2″ | 8 | 7/8″ | 7/8″ | R-24 |

| 2-1/16″ | 10,000 | 7-7/8″ | 8 | 3/4″ | 3/4″ | BX-152 |

| 2-1/16″ | 15,000 | 8-3/4″ | 8 | 7/8″ | 7/8″ | BX-152 |

| 2-1/16″ | 20,000 | 11-5/16″ | 8 | 1-1/8″ | 1-1/8″ | BX-152 |

| 2-9/16″ | 2,000 | 7-1/2″ | 8 | 3/4″ | 5-1/4″ | R-26 |

| 2-9/16″ | 3,000/5,000 | 9-5/8″ | 8 | 1″ | 7″ | R-27 |

| 2-9/16″ | 10,000 | 9-1/8″ | 8 | 7/8″ | 6-1/4″ | BX-153 |

| 2-9/16″ | 15,000 | 10″ | 8 | 1″ | 7″ | BX-153 |

| 2-9/16″ | 20,000 | 12-13/16″ | 8 | 1-1/4″ | 9-1/2″ | BX-153 |

| 3-1/8″ | 2,000 | 8-1/4″ | 8 | 3/4″ | 5-1/2″ | R-31 |

| 3-1/8″ | 3,000 | 9-1/2″ | 8 | 7/8″ | 6-1/4″ | R-31 |

| 3-1/8″ | 5,000 | 10-1/2″ | 8 | 1-1/8″ | 7-3/4″ | R-35 |

| 3-1/16″ | 10,000 | 10-5/8″ | 8 | 1″ | 7-1/4″ | BX-154 |

| 3-1/16″ | 15,000 | 11-5/16″ | 8 | 1-1/8″ | 8″ | BX-154 |

| 3-1/16″ | 20,000 | 14-1/16″ | 8 | 1-3/8″ | 10-3/4″ | BX-154 |

| 4-1/16″ | 2,000 | 10-3/4″ | 8 | 7/8″ | 6-1/4″ | R-37 |

| 4-1/16″ | 3,000 | 11-1/2″ | 8 | 1-1/8″ | 7-1/2″ | R-37 |

| 4-1/16″ | 5,000 | 12-1/4″ | 8 | 1-1/8″ | 8-3/8″ | BX-155 |

| 4-1/16″ | 20,000 | 17-9/16″ | 8 | 1-3/4″ | 12-3/4″ | BX-155 |

| 5-1/8″ | 5,000 | 14-3/4″ | 8 | 1-1/2″ | 10-3/4″ | R-44 |

| 7-1/16″ | 2,000 | 14″ | 12 | 1″ | 7-1/2″ | R-45 |

| 7-1/16″ | 3,000 | 15″ | 12 | 1-1/8″ | 8-1/2″ | R-45 |

| 7-1/16″ | 5,000 | 15-1/2″ | 12 | 1-3/8″ | 11-1/4″ | R-46 |

| 7-1/16″ | 10,000 | 18-7/8″ | 12 | 1-1/2″ | 11-3/4″ | BX-156 |

| 7-1/16″ | 15,000 | 19-7/8″ | 16 | 1-1/2″ | 13″ | BX-156 |

| 7-1/16″ | 20,000 | 24-13/16″ | 16 | 2″ | 17-3/4″ | BX-156 |

| 9″ | 2,000 | 16-1/2″ | 12 | 1-1/8″ | 8-1/2″ | R-49 |

| 9″ | 3,000 | 18-1/2″ | 12 | 1-3/8″ | 9-1/2″ | R-49 |

| 9″ | 5,000″ | 19″ | 12 | 1-5/8″ | 12-1/2″ | R-50 |

| 9″ | 10,000 | 21-3/4″ | 16 | 1-1/2″ | 13-1/4″ | BX-157 |

| 9″ | 15,000 | 25-1/2″ | 16 | 1-7/8″ | 16″ | BX-157 |

| 11″ | 2,000 | 20″ | 16 | 1-1/4″ | 9-1/4″ | R-53 |

| 11″ | 3,000 | 21-1/2″ | 16 | 1-3/8″ | 10″ | R-53 |

| 11″ | 5,000 | 23″ | 12 | 1-7/8″ | 14-1/4″ | R-54 |

| 11″ | 10,000 | 25-3/4″ | 16 | 1-3/4″ | 15-3/8″ | BX-158 |

| 11″ | 15,000 | 32″ | 20 | 2″ | 19-1/2″ | BX-158 |

| 13-5/8″ | 2,000 | 22″ | 20 | 1-1/4″ | 9-1/2″ | R-57 |

| 13-5/8″ | 3,000 | 24″ | 20 | 1-3/8″ | 10-3/4″ | R-57 |

| 13-5/8″ | 5,000 | 26-1/2″ | 16 | 1-5/8″ | 12-3/4″ | BX-160 |

| 13-5/8″ | 10,000 | 30-1/4″ | 20 | 1-7/8″ | 17-3/4″ | BX-159 |

| 13-5/8″ | 15,000 | 34-7/8″ | 20 | 2-1/4″ | 21″ | BX-159 |

| 16-3/4″ | 2,000 | 27″ | 20 | 1-1/2″ | 10-3/4″ | R-65 |

| 16-3/4″ | 3,000 | 27-3/4″ | 20 | 1-5/8″ | 12-1/4″ | R-66 |

| 16-3/4″ | 5,000 | 30-3/8″ | 16 | 1-78″ | 14-3/4″ | BX-162 |

| 16-3/4″ | 10,000 | 34-5/16″ | 24 | 1-7/8″ | 17-3/4″ | BX-162 |

| 18-3/4″ | 5,000 | 35-5/8″ | 20 | 2″ | 18″ | BX-163 |

| 16-3/4″ | 10,000 | 40-15/16″ | 24 | 2-1/4″ | 23″ | BX-164 |

| 20-3/4″ | 3,000 | 33-3/4″ | 20 | 2″ | 15-1/4″ | R-74 |

| 21-1/4″ | 2,000 | 32″ | 24 | 1-5/8″ | 12-1/2″ | R-73 |

| 21-1/4″ | 5,000 | 39″ | 24 | 2″ | 19″ | BX-165 |

| 21-1/4″ | 10,000 | 45″ | 24 | 2-1/2″ | 24-3/4″ | BX-166 |

| 26-3/4″ | 2,000 | 41″ | 20 | 1-3/4″ | 14-1/4″ | BX-167 |

| 21-1/4″ | 3,000 | 43-3/8″ | 24 | 2″ | 17-1/2″ | BX-168 |

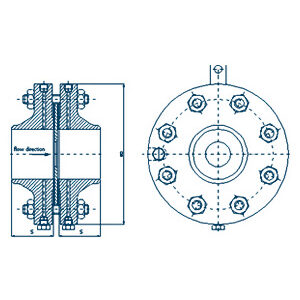

Dimension of 2000 PSI Type API 6A/6B Blind and Welding Neck Flanges

| Size | B | OD | C | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | R/RX |

| 2 1/16″ | 53.2 | 165 | 3 | 108 | 82.55 | 7.9 | 33.4 | 25.4 | 84 | 127 | 8 | 20 | 81 | 60.3 | 53.3 | 23 |

| 2 9/16″ | 65.9 | 190 | 3 | 127 | 101.6 | 7.9 | 36.6 | 28.6 | 100 | 149.2 | 8 | 23 | 88 | 73 | 63.5 | 26 |

| 3 1/8″ | 81.8 | 210 | 3 | 146 | 123.83 | 7.9 | 39.7 | 31.8 | 117 | 168.3 | 8 | 23 | 91 | 88.9 | 78.7 | 31 |

| 4 1/16″ | 108.7 | 275 | 3 | 175 | 149.23 | 7.9 | 46.1 | 38.1 | 152 | 215.9 | 8 | 26 | 110 | 114.3 | 103.1 | 37 |

| 5 1/8″ | 131 | 330 | 3 | 210 | 180.98 | 7.9 | 52.4 | 44.5 | 189 | 266.7 | 8 | 29 | 122 | 141.3 | 122.9 | 41 |

| 7 1/16″ | 181.8 | 355 | 6 | 241 | 211.15 | 7.9 | 55.6 | 47.6 | 222 | 292.1 | 12 | 29 | 126 | 168.3 | 147.1 | 45 |

| 9″ | 229.4 | 420 | 6 | 302 | 269.88 | 7.9 | 63.5 | 55.6 | 273 | 349.3 | 12 | 32 | 141 | 219.1 | 199.1 | 49 |

| 11″ | 280.2 | 510 | 6 | 356 | 323.85 | 7.9 | 71.5 | 63.5 | 343 | 431.8 | 16 | 35 | 160 | 273 | 248.4 | 53 |

| 13 5/8″ | 346.9 | 560 | 6 | 413 | 381 | 7.9 | 74.7 | 66.7 | 400 | 489 | 20 | 35 | – | – | – | 57 |

| 16 3/4″ | 426.2 | 685 | 6 | 508 | 469.9 | 7.9 | 84.2 | 76.2 | 495 | 603.2 | 20 | 42 | – | – | – | 65 |

| 21 1/4″ | 540.5 | 815 | 6 | 635 | 584.2 | 9.7 | 98.5 | 88.9 | 610 | 723.9 | 24 | 45 | – | – | – | 73 |

| Flanges for Wellhead and Christmas Tree Equipment Weld Neck, Integral, Blinds, Targets and Test Blinds-Pressure Ratings |

|||

| Max Working Pressure |

2000 PSI |

3000 PSI |

5000 PSI |

| Test Pressure | 3000 PSI | 4500 PSI | 7500 PSI |

| Product Spec Levels |

1, 2, 3 and 4 | 1, 2, 3 and 4 | 1, 2, 3 and 4 |

| API Temp Rating |

K (-60 ° C) to Y (+345 ° C) |

K (-60 ° C) to Y (+345 ° C) |

K (-60 ° C) to Y (+345 ° C) |

| Integral, Blind, Target Blind and Test Flanges | |||

| Min. Yield | 60 000 PSI | 60 000 PSI | 60 000 PSI |

| Min. Tensile | 85 000 PSI | 85 000 PSI | 85 000 PSI |

| Material | API 60K | API 60K | API 60K |

| Weld Neck Flanges | |||

| Min. Yield | 45 000 PSI | 45 000 PSI | 45 000 PSI |

| Min. Tensile | 70 000 PSI | 70 000 PSI | 70 000 PSI |

| Material | API 45K | API 45K | API 45K |

| Flanges for Wellhead and Christmas Tree Equipment Weld Neck, Integral, Blinds, Targets and Test Blinds-Pressure Ratings |

|||

| Max Working Pressure |

10 000 PSI |

15 000 PSI |

20 000 PSI |

| Test Pressure | 15 000 PSI | 22 500 PSI | 30 000 PSI |

| Product Spec Levels |

1, 2, 3 and 4 | 1, 2, 3 and 4 | 1, 2, 3 and 4 |

| API Temp Rating |

K (-60 ° C) to Y (+345 ° C) |

K (-60 ° C) to Y (+345 ° C) |

K (-60 ° C) to Y (+345 ° C) |

| Integral, Blind, Target Blind and Test Flanges | |||

| Min. Yield | 60 000 PSI | 75 000 PSI | 75 000 PSI |

| Min. Tensile | 85 000 PSI | 95 000 PSI | 95 000 PSI |

| Material | API 60K | API 75K | API 75K |

| Weld Neck Flanges | |||

| Min. Yield | 60 000 PSI | 75 000 PSI | 75 000 PSI |

| Min. Tensile | 85 000 PSI | 95 000 PSI | 95 000 PSI |

| Material | API 60K | API 75K | API 75K |

Dimension of 3000 PSI Type API 6A/6B Blind and Welding Neck Flanges

| Size | B | OD | C | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | R/RX |

| 2 1/16″ | 53.2 | 215 | 3 | 124 | 95.25 | 7.9 | 46.1 | 38.1 | 104.8 | 165.1 | 8 | 26 | 109.6 | 60.3 | 50 | 24 |

| 2 9/16″ | 65.9 | 245 | 3 | 137 | 107.95 | 7.9 | 49.3 | 41.3 | 123.8 | 190.5 | 8 | 29 | 112.7 | 73 | 59.7 | 27 |

| 3 1/8″ | 81.8 | 240 | 3 | 156 | 123.83 | 7.9 | 46.1 | 38.1 | 127 | 190.5 | 8 | 26 | 109.5 | 88.9 | 74.4 | 31 |

| 4 1/16″ | 108.7 | 290 | 3 | 181 | 149.23 | 7.9 | 52.4 | 44.4 | 158.8 | 235 | 8 | 32 | 122.2 | 114.3 | 98 | 37 |

| 5 1/8″ | 131 | 350 | 3 | 216 | 180.98 | 7.9 | 58.8 | 50.8 | 190.5 | 279.4 | 8 | 35 | 134.9 | 141.3 | 122.9 | 41 |

| 7 1/16″ | 181.8 | 380 | 6 | 241 | 211.15 | 7.9 | 63.5 | 55.6 | 235 | 317.5 | 12 | 32 | 147.6 | 168.3 | 147.1 | 45 |

| 9″ | 229.4 | 470 | 6 | 308 | 269.88 | 7.9 | 71.5 | 63.5 | 298.5 | 393.7 | 12 | 39 | 169.9 | 219.1 | 189.7 | 49 |

| 11″ | 280.2 | 545 | 6 | 362 | 323.85 | 7.9 | 77.8 | 69.9 | 368.3 | 469.9 | 16 | 39 | 192.1 | 273 | 237.2 | 53 |

| 13 5/8″ | 346.9 | 610 | 6 | 419 | 381 | 7.9 | 87.4 | 79.4 | 419.1 | 533.4 | 20 | 39 | – | – | – | 57 |

| 16 3/4″ | 426.2 | 705 | 6 | 524 | 469.9 | 11.2 | 100.1 | 88.9 | 508 | 616 | 20 | 45 | – | – | – | 66 |

| 20 3/4″ | 527.8 | 855 | 6 | 648 | 584.2 | 12.7 | 120.7 | 108 | 622.3 | 749.3 | 20 | 54 | – | – | – | 74 |

Dimension of 5000 PSI Type API 6A/6B Blind and Welding Neck Flanges

| Size | B | OD | C | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | R/RX |

| 2 1/16″ | 53.2 | 215 | 3 | 124 | 95.25 | 7.9 | 46.1 | 38.1 | 104.8 | 165.1 | 8 | 26 | 109.5 | 60.3 | 43.7 | 24 |

| 2 9/16″ | 65.9 | 245 | 3 | 137 | 107.95 | 7.9 | 49.3 | 41.3 | 123.8 | 190.5 | 8 | 29 | 112.7 | 73 | 54.9 | 27 |

| 3 1/8″ | 81.8 | 265 | 3 | 168 | 136.53 | 7.9 | 55.6 | 47.7 | 133.3 | 203.2 | 8 | 32 | 125.4 | 88.9 | 67.5 | 35 |

| 4 1/16″ | 108.7 | 310 | 3 | 194 | 161.93 | 7.9 | 62 | 54 | 161.9 | 241.3 | 8 | 35 | 131.8 | 114.3 | 88.1 | 39 |

| 5 1/8″ | 131 | 375 | 3 | 229 | 193.68 | 7.9 | 81 | 73.1 | 196.8 | 292.1 | 8 | 42 | 163.5 | 141.3 | 110.3 | 44 |

| 7 1/16″ | 181.8 | 395 | 6 | 248 | 211.15 | 9.7 | 92.1 | 82.6 | 228.6 | 317.5 | 12 | 39 | 181 | 168.3 | 132.6 | 46 |

| 9″ | 229.4 | 485 | 6 | 318 | 269.88 | 11.2 | 103.2 | 92.1 | 292.1 | 393.7 | 12 | 45 | 223.8 | 219.1 | 173.8 | 50 |

| 11″ | 280.2 | 585 | 6 | 371 | 323.85 | 11.2 | 119.1 | 108 | 368.3 | 482.6 | 12 | 51 | 265.1 | 273.1 | 216.7 | 54 |

Dimension of 10000 PSI Type API 6A/6B Blind and Welding Neck Flanges

| Size | B | OD | C | E1 | Q | G | K | T | J1 | J2 | J3 | J4 | R | BC | N | H | BX |

| 1 13/16″ | 46.8 | 185 | 3 | – | 5.56 | 77.77 | 105 | 42.1 | 88.9 | 65.1 | 48.5 | – | 10 | 146.1 | 8 | 23 | 151 |

| 2 1/16″ | 53.2 | 200 | 3 | – | 5.95 | 86.23 | 111 | 44.1 | 100 | 74.7 | 51.6 | – | 10 | 158.8 | 8 | 23 | 152 |

| 2 9/16″ | 65.9 | 230 | 3 | – | 6.75 | 102.77 | 132 | 51.2 | 120.7 | 92.1 | 57.2 | – | 10 | 184.2 | 8 | 26 | 153 |

| 3 1/16″ | 78.6 | 270 | 3 | – | 7.54 | 119 | 152 | 58.4 | 142.1 | 110.2 | 63.5 | – | 10 | 215.9 | 8 | 29 | 154 |

| 4 1/16″ | 104 | 315 | 3 | – | 8.33 | 150.62 | 185 | 70.3 | 182.6 | 146.1 | 73.1 | – | 10 | 258.8 | 8 | 32 | 155 |

| 5 1/8″ | 131 | 360 | 3 | 9.5 | 9.53 | 176.66 | 221 | 79.4 | 223.8 | 182.6 | 81 | 6.4 | 10 | 300 | 12 | 32 | 169 |

| 7 1/16″ | 180.2 | 480 | 6 | 11.1 | 11.11 | 241.83 | 302 | 103.2 | 301.6 | 254 | 95.3 | 9.7 | 16 | 403.2 | 12 | 42 | 156 |

| 9 “ | 229.4 | 550 | 6 | 12.7 | 12.7 | 299.06 | 359 | 123.9 | 374.7 | 327.1 | 93.7 | 9.7 | 16 | 476.3 | 16 | 42 | 157 |

| 11″ | 280.2 | 655 | 6 | 14.3 | 14.29 | 357.23 | 429 | 141.3 | 450.9 | 400.1 | 103.2 | 14.2 | 16 | 565.2 | 16 | 48 | 158 |

| 13 5/8″ | 346.9 | 770 | 6 | 15.9 | 15.88 | 432.64 | 518 | 168.3 | 552.5 | 495.3 | 114.3 | 17.5 | 16 | 673.1 | 20 | 51 | 159 |

| 16 3/4″ | 426.2 | 870 | 6 | 8.3 | 8.33 | 478.33 | 576 | 168.3 | 655.6 | 601.7 | 76.2 | 30.2 | 19 | 776.3 | 24 | 51 | 162 |

| 18 3/4″ | 477 | 1040 | 6 | 18.3 | 18.26 | 577.9 | 697 | 223.1 | 752.5 | 674.7 | 155.6 | 25.4 | 16 | 925.5 | 24 | 61 | 164 |

| 21 1/4″ | 540.5 | 1145 | 6 | 19.1 | 19.05 | 647.88 | 781 | 241.3 | 847.7 | 762 | 165.1 | 31.8 | 21 | 1022.4 | 24 | 67 | 166 |

Flange Section - Integral Flange

| Nominal Size and Bore |

Max Bore |

Out Side Dia |

Tolerance | Max Chamfer |

| B | D | D | C | |

| 2000 PSI | ||||

| 26¾ | 26.78 | 41 | ± 0.12 | 0.25 |

| 30 | 30.03 | 44.19 | ± 0.12 | 0.25 |

| 3000 PSI | ||||

| 26¾ | 26.78 | 43.38 | ± 0.12 | 0.25 |

| 30 | 30.03 | 46.68 | ± 0.12 | 0.25 |

| 5000 PSI | ||||

| 13.3/8 | 13.66 | 26.5 | ± 0.12 | 0.25 |

| 16¾ | 16.78 | 30.38 | ± 0.12 | 0.25 |

| 18¾ | 18.78 | 35.62 | ± 0.12 | 0.25 |

| 21¾ | 21.28 | 39 | ± 0.12 | 0.25 |

| 10000 PSI | ||||

| 1.13/16 | 1.84 | 7.38 | ± 0.06 | 0.12 |

| 2.1/16 | 2.09 | 7.88 | ± 0.06 | 0.12 |

| 2.9/16 | 2.59 | 9.12 | ± 0.06 | 0.12 |

| 3.1/16 | 3.09 | 10.62 | ± 0.06 | 0.12 |

| 4.1/16 | 4.09 | 12.44 | ± 0.06 | 0.12 |

| 5.1/8 | 5.16 | 14.06 | ± 0.06 | 0.12 |

| 7.1/16 | 7.09 | 18.88 | ± 0.12 | 0.25 |

| 9 | 9.03 | 21.75 | ± 0.12 | 0.25 |

| 11 | 11.03 | 25.75 | ± 0.12 | 0.25 |

| 13.5/8 | 13.66 | 30.25 | ± 0.12 | 0.25 |

| 16¾ | 16.78 | 34.31 | ± 0.12 | 0.25 |

| 18¾ | 18.78 | 40.94 | ± 0.12 | 0.25 |

| 21¼ | 21.28 | 45 | ± 0.12 | 0.25 |

| 15000 PSI | ||||

| 1.13/16 | 1.84 | 8.19 | ± 0.06 | 0.12 |

| 2.1/16 | 2.09 | 8.75 | ± 0.06 | 0.12 |

| 2.9/16 | 2.59 | 10 | ± 0.06 | 0.12 |

| 3.1/16 | 3.09 | 11.31 | ± 0.06 | 0.12 |

| 4.1/16 | 4.09 | 14.19 | ± 0.06 | 0.12 |

| 5.1/8 | 5.16 | 16.5 | ± 0.06 | 0.12 |

| 7.1/16 | 7.09 | 19.88 | ± 0.12 | 0.25 |

| 9 | 9.03 | 25.5 | ± 0.12 | 0.25 |

| 11 | 11.03 | 32 | ± 0.12 | 0.25 |

| 13.5/8 | 13.66 | 34.88 | ± 0.12 | 0.25 |

| 18¾ | 18.78 | 45.75 | ± 0.12 | 0.25 |

| 20000 PSI | ||||

| 1.13/16 | 1.84 | 10.12 | ± 0.06 | 0.12 |

| 2.1/16 | 2.09 | 11.31 | ± 0.06 | 0.12 |

| 2.9/16 | 2.59 | 12.81 | ± 0.06 | 0.12 |

| 3.1/16 | 3.09 | 14.06 | ± 0.06 | 0.12 |

| 4.1/16 | 4.09 | 17.56 | ± 0.06 | 0.12 |

| 7.1/16 | 7.09 | 25.81 | ± 0.12 | 0.25 |

| 9 | 9.03 | 31.69 | ± 0.12 | 0.25 |

| 11 | 11.03 | 34.75 | ± 0.12 | 0.25 |

| 13.5/8 | 13.66 | 45.75 | ± 0.12 | 0.25 |

| Nominal Size and Bore |

Dia Raised Face |

Total THK |

Large Dia Hub |

Small Dia Hub |

| F | T | A | E | |

| 2000 PSI | ||||

| 26¾ | 31.69 | 4.97 | 32.91 | 29.25 |

| 30 | 35.75 | 5.28 | 36.69 | 32.8 |

| 3000 PSI | ||||

| 26¾ | 32.75 | 6.34 | 34.25 | 30.56 |

| 30 | 36.31 | 6.58 | 38.19 | 34.3 |

| 5000 PSI | ||||

| 13.3/8 | 18 | 4.44 | 18.94 | 16.69 |

| 16¾ | 21.06 | 5.13 | 21.88 | 20.75 |

| 18¾ | 24.69 | 6.53 | 26.56 | 23.56 |

| 21¾ | 27.62 | 7.12 | 29.88 | 26.75 |

| 10000 PSI | ||||

| 1.13/16 | 4.12 | 1.66 | 3.5 | 2.56 |

| 2.1/16 | 4.38 | 1.73 | 3.94 | 2.94 |

| 2.9/16 | 5.19 | 2.02 | 4.75 | 3.62 |

| 3.1/16 | 6 | 2.3 | 5.59 | 4.34 |

| 4.1/16 | 7.28 | 2.77 | 7.19 | 5.75 |

| 5.1/8 | 8.69 | 3.12 | 8.81 | 7.19 |

| 7.1/16 | 11.88 | 4.06 | 11.88 | 10 |

| 9 | 14.12 | 4.88 | 14.75 | 12.88 |

| 11 | 16.88 | 5.56 | 17.75 | 15.75 |

| 13.5/8 | 20.38 | 6.62 | 21.75 | 19.5 |

| 16¾ | 22.69 | 6.62 | 25.81 | 23.69 |

| 18¾ | 27.44 | 8.78 | 29.62 | 26.56 |

| 21¼ | 30.75 | 9.5 | 33.38 | 30 |

| 15000 PSI | ||||

| 1.13/16 | 4.19 | 1.78 | 3.84 | 2.81 |

| 2.1/16 | 4.5 | 2 | 4.38 | 3.25 |

| 2.9/16 | 5.25 | 2.25 | 5.06 | 3.94 |

| 3.1/16 | 6.06 | 2.53 | 6.06 | 4.81 |

| 4.1/16 | 7.62 | 3.09 | 7.69 | 6.25 |

| 5.1/8 | 8.88 | 3.88 | 9.62 | 7.88 |

| 7.1/16 | 12 | 4.6 | 12.81 | 10.88 |

| 9 | 15 | 5.75 | 17 | 13.75 |

| 11 | 17.88 | 7.38 | 23 | 16.81 |

| 13.5/8 | 21.31 | 8.06 | 23.44 | 20.81 |

| 18¾ | 28.44 | 10.06 | 32 | 28.75 |

| 20000 PSI | ||||

| 1.13/16 | 4.62 | 2.5 | 5.25 | 4.31 |

| 2.1/16 | 5.19 | 2.81 | 6.06 | 5 |

| 2.9/16 | 5.94 | 3.12 | 6.81 | 5.69 |

| 3.1/16 | 6.75 | 3.38 | 7.56 | 6.31 |

| 4.1/16 | 8.62 | 4.19 | 9.56 | 8.12 |

| 7.1/16 | 13.88 | 6.5 | 15.19 | 13.31 |

| 9 | 17.38 | 8.06 | 18.94 | 16.88 |

| 11 | 19.88 | 8.81 | 22.31 | 20 |

| 13.5/8 | 24.19 | 11.5 | 27.31 | 24.75 |

AP 6A/6B Flanges Tolerance

| Dia Bolt Holes |

Bolt Hole Tolerance |

Length Bolts |

Ring No (R or RX) |

|

| 2000 PSI | ||||

| 26¾ | 1.88 | +0.09 | 13.75 | 167 |

| 30 | 1.75 | +0.09 | 14.25 | 303 |

| 3000 PSI | ||||

| 26¾ | 2.12 | +0.09 | 17 | 168 |

| 30 | 2 | +0.09 | 17.75 | 303 |

| 5000 PSI | ||||

| 13.3/8 | 1.75 | +0.09 | 12.5 | 160 |

| 16¾ | 2 | +0.09 | 14.5 | 162 |

| 18¾ | 2.12 | +0.09 | 17.5 | 163 |

| 21¾ | 2.12 | +0.09 | 18.75 | 165 |

| 10000 PSI | ||||

| 1.13/16 | 0.88 | +0.06 | 5 | 151 |

| 2.1/16 | 0.88 | +0.06 | 5.2 | 152 |

| 2.9/16 | 1 | +0.06 | 6 | 153 |

| 3.1/16 | 1.12 | +0.06 | 6.75 | 154 |

| 4.1/16 | 1.25 | +0.06 | 8 | 155 |

| 5.1/8 | 1.25 | +0.06 | 8.75 | 169 |

| 7.1/16 | 1.62 | +0.09 | 11.25 | 156 |

| 9 | 1.62 | +0.09 | 13 | 157 |

| 11 | 1.88 | +0.09 | 15 | 158 |

| 13.5/8 | 2 | +0.09 | 17.25 | 159 |

| 16¾ | 2 | +0.09 | 17.5 | 162 |

| 18¾ | 2.38 | +0.09 | 22.5 | 164 |

| 21¼ | 2.62 | +0.09 | 24.5 | 166 |

| 15000 PSI | ||||

| 1.13/16 | 1 | +0.06 | 5.5 | 151 |

| 2.1/16 | 1 | +0.06 | 6 | 152 |

| 2.9/16 | 1.12 | +0.06 | 6.75 | 153 |

| 3.1/16 | 1.25 | +0.06 | 7.5 | 154 |

| 4.1/16 | 1.5 | +0.06 | 9.25 | 155 |

| 5.1/8 | 1.62 | +0.09 | 11.5 | 169 |

| 7.1/16 | 1.62 | +0.09 | 12.75 | 156 |

| 9 | 2 | +0.09 | 15.75 | 157 |

| 11 | 2.12 | +0.09 | 19.25 | 158 |

| 13.5/8 | 2.38 | +0.09 | 21.25 | 159 |

| 18¾ | 3.12 | +0.12 | 26.75 | 164 |

| 20000 PSI | ||||

| 1.13/16 | 1.12 | +0.06 | 7.5 | 151 |

| 2.1/16 | 1.25 | +0.06 | 8.25 | 152 |

| 2.9/16 | 1.38 | +0.06 | 9.25 | 153 |

| 3.1/16 | 1.5 | +0.06 | 10 | 154 |

| 4.1/16 | 1.88 | +0.09 | 12.25 | 155 |

| 7.1/16 | 2.12 | +0.09 | 17.5 | 156 |

| 9 | 2.62 | +0.09 | 22.38 | 157 |

| 11 | 2.88 | +0.09 | 23.75 | 158 |

| 13.5/8 | 3.12 | +0.12 | 30 | 159 |

API 6A-6B Flanges Material

| Carbon Steel API 6A-6B Flanges | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Stainless Steel API 6A-6B Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Alloy Steel API 6A-6B Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium API 6A-6B Flanges | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper API 6A-6B Flanges | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel API 6A-6B Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass API 6A-6B Flanges | 3602 / 2604 / H59 / H62 / etc. |

| Inconel API 6A-6B Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 API 6A-6B Flanges |

| Hastelloy API 6A-6B Flanges | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel API 6A-6B Flanges | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 API 6A-6B Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium API 6A-6B Flanges | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel API 6A-6B Flanges | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex API 6A-6B Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex API 6A-6B Flanges | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy API 6A-6B Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 Smo API 6A-6B Flanges | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic API 6A-6B Flanges | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other API 6A-6B Flanges Material | Tin bronze, Aluminum bronze, Lead bronze |