ANSI B16.5 Orifice Flanges

India’s Leading ANSI B16.36 SS RF Orifice Flanges, Competitive Price of ANSI B16.36 Raised Faced Orifice Flanges, Class 600 Raised Face or Flat Face, ANSI B16.5 Orifice Raised Face Flange Manufacturer & Supplier in India.

Kanak Steel & Engg Co. is an eminent manufacturing, exporting, supplying and trading unit of ANSI B16.5 Orifice Flanges, which are to be had within the widest sort of wall thicknesses and substances within the industry.

They are becoming add-ons which might be used extensively in diverse commercial sectors in pipe becoming. It is a becoming mounted among lengths of pipe or tube permitting extrude of direction, commonly within the handy direction. Stainless Steel ANSI B16.5 Orifice Flanges are commonly used for becoming a member of Female BSP threads, and are pretty secure to be used in meals and beverage applications. They have a protracted tapered hub and sluggish transition of thickness within the place of the butt weld becoming a member of them to the pipe.

It is a strain maintaining plate with one open cease and one stable cease related in with a tie-bar or web. In fashionable method, the open cease shapes seals among the flanges and allows an everyday glide of flowing everywhere in the pipe work. Carbon Steel ANSI B16.5 Orifice Flanges had been evolved to be used on small length excessive strain piping. Smooth bore situations may be effortlessly attained with the aid of using grinding the inner weld. They are typically utilized in chemical procedure piping, and are being provided within the path of appropriate check certificate of fashionable uncooked substances and completed products.

They have a decrease preliminary fee than different flanges due to the fact they require much less accuracy in slicing pipe to length, and that they offer a more ease of alignment in assembly. However, their calculated energy beneath inner strain is about -thirds the energy of different flanges, and their existence beneath fatigue is one-1/3 shorter. Super Duplex Steel ANSI B16.5 Orifice Flanges may be assembled without welding and may be utilized in extraordinarily excessive strain services, at or close to atmospheric strain, in which alloy metal is important for energy. They aren’t proper for situations regarding temperature or bending stresses or beneath cyclic situations in which leakage via the threads can also additionally occur.

Largest Manufacturer & Supplier of Carbon Steel A105 Orifice Flanges, Alloy Steel Orifice Flanges, Class 600 Monel Orifice Raised Face Flanges, ANSI B16.5 Nickel Alloy Raised Face Orifice Flanges, ANSI 16.5 Class 300 Stainless Steel Orifice Flanges Manufacturer, Copper Nickel Orifice Flanges, in Mumbai, India.

Specification Of ANSI B16.5 Orifice Flanges

| Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

|---|---|

| ANSI B16.5 Orifice Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS SP44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ANSI B16.5 Orifice Flange Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ANSI B16.5 Orifice Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Orifice Flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| ANSI B16.5 Orifice Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| ANSI B16.5 Orifice Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Orifice Flanges Production technique | Orifice, Heat treated and machined |

| Orifice Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing

AS, ANSI, BS, DIN and JIS |

| Orifice Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Orifice Flanges Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Orifice Flange Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of Orifice Flange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. ASTM A182 Orifice Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI FlangeB.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British standard (BS)DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 ASTM A182 F316 Stainless Steel Flanges The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Orifice Flange Uses & application | Bitumen upgraders. Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

| Orifice Plate Flanges Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi & Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

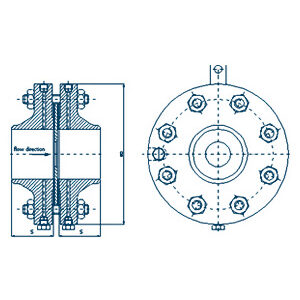

Dimension of ANSI B16.5 Orifice Flanges

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | Welding Neck Length | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 125 | 36.6 | 54 | 33.4 | 81 | 50.8 | 2 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 4.5 |

| 1 1/2 | 40 | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 2 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 6.5 |

| 2 | 50 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 2 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 7 |

| 2 1/2 | 65 | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 2 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 7.5 |

| 3 | 80 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 2 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 9.4 |

| 4 | 100 | 255 | 36.6 | 146 | 114.3 | 90 | 157.2 | 2 | 200 | 12.7 | 8 | 3/4 | 135 | 7/8 | M20 | 13.2 |

| 6 | 150 | 320 | 36.6 | 206 | 168.3 | 98 | 215.9 | 2 | 269.9 | 12.7 | 12 | 3/4 | 135 | 7/8 | M20 | 14.6 |

| 8 | 200 | 380 | 39.7 | 260 | 219.1 | 110 | 269.9 | 2 | 330.2 | 12.7 | 12 | 7/8 | 145 | 1 | M24 | 30 |

| 10 | 250 | 445 | 46.1 | 321 | 273 | 116 | 323.8 | 2 | 387.3 | 12.7 | 16 | 1 | 165 | 1 1/8 | M27 | 41 |

| 12 | 300 | 520 | 49.3 | 375 | 323.8 | 129 | 381 | 2 | 450.8 | 12.7 | 16 | 1 1/8 | 180 | 1 1/4 | M30 | 62 |

| 14 | 350 | 585 | 52.4 | 425 | 355.6 | 141 | 412.8 | 2 | 514.4 | 12.7 | 20 | 1 1/8 | 185 | 1 1/4 | M30 | 84 |

| 16 | 400 | 650 | 55.6 | 483 | 406.4 | 144 | 469.9 | 2 | 571.5 | 12.7 | 20 | 1 1/4 | 195 | 1 3/8 | M33 | 111 |

| 18 | 450 | 710 | 58.8 | 533 | 457 | 157 | 533.4 | 2 | 628.6 | 12.7 | 24 | 1 1/4 | 205 | 1 3/8 | M33 | 138 |

| 20 | 500 | 775 | 62 | 587 | 508 | 160 | 584.2 | 2 | 685.8 | 12.7 | 24 | 1 1/4 | 215 | 1 3/8 | M33 | 171 |

| 24 | 600 | 915 | 68.3 | 702 | 610 | 167 | 692.2 | 2 | 812.8 | 12.7 | 24 | 1 1/2 | 240 | 1 5/8 | M39 | 247 |

ANSI B16.5 Class 150 Orifice Flanges Dimensions

| NPS | O | C | R | X | A | Y | TT | No. of holes | Diameter of holes | Diameter of bolts | Diameter of bolt circle | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | 1″ | 4.88 | 1.5 | 2 | 2.12 | 1.32 | 3.25 | 01/04/07 | 4 | 0.69 | 5/8″ | 3.5 |

| Millimeter | 124 | 38.1 | 50.8 | 53.8 | 33.5 | 82.6 | 6.4 | 17.5 | 15.9 | 88.9 | ||

| Inch | 1 1/2″ | 6.12 | 1.5 | 2.88 | 2.75 | 1.9 | 3.38 | 01/04/07 | 4 | 0.81 | 3/4″ | 4.5 |

| Millimeter | 155.4 | 38.1 | 73.2 | 69.9 | 48.3 | 85.9 | 6.4 | 20.6 | 19.1 | 114.3 | ||

| Inch | 2″ | 6.5 | 1.5 | 3.62 | 3.31 | 2.38 | 3.38 | 01/04/07 | 8 | 0.69 | 5/8″ | 5 |

| Millimeter | 165.1 | 38.1 | 91.9 | 84.1 | 60.5 | 85.9 | 6.4 | 17.5 | 15.9 | 127 | ||

| Inch | 2 1/2″ | 7.5 | 1.5 | 4.12 | 3.94 | 2.88 | 3.5 | 01/04/07 | 8 | 0.81 | 3/4″ | 5.88 |

| Millimeter | 190.5 | 38.1 | 104.6 | 100.1 | 73.2 | 88.9 | 6.4 | 20.6 | 19.1 | 149.4 | ||

| Inch | 3″ | 8.25 | 1.5 | 5 | 4.62 | 3.5 | 3.5 | 03/08/07 | 8 | 0.81 | 3/4″ | 6.62 |

| Millimeter | 209.6 | 38.1 | 127 | 117.3 | 88.9 | 88.9 | 9.5 | 20.6 | 19.1 | 168.1 | ||

| Inch | 4″ | 10 | 1.5 | 6.19 | 5.75 | 4.5 | 3.62 | 01/02/07 | 8 | 0.81 | 3/4″ | 7.88 |

| Millimeter | 254 | 38.1 | 157.2 | 146.1 | 114.3 | 91.9 | 12.7 | 20.6 | 19.1 | 200.2 | ||

| Inch | 6″ | 12.5 | 1.5 | 8.5 | 8.12 | 6.63 | 3.94 | 01/02/07 | 12 | 0.88 | 3/4″ | 10.62 |

| Millimeter | 317.5 | 38.1 | 215.9 | 206.2 | 168.4 | 100.1 | 12.7 | 22.4 | 19.1 | 269.7 | ||

| Inch | 8″ | 15 | 1.62 | 10.62 | 10.25 | 8.63 | 4.38 | 01/02/07 | 12 | 1 | 7/8″ | 13 |

| Millimeter | 381 | 41.1 | 269.7 | 260.4 | 219.2 | 111.3 | 12.7 | 25.4 | 22.2 | 330.2 | ||

| Inch | 10″ | 17.5 | 1.88 | 12.75 | 12.62 | 10.75 | 4.62 | 01/02/07 | 16 | 1.12 | 1″ | 15.25 |

| Millimeter | 444.5 | 47.8 | 323.9 | 320.5 | 273.1 | 117.3 | 12.7 | 28.4 | 25.4 | 387.4 | ||

| Inch | 12″ | 20.5 | 2 | 15 | 14.75 | 12.75 | 5.12 | 01/02/07 | 16 | 1.25 | 1 1/8″ | 17.75 |

| Millimeter | 520.7 | 50.8 | 381 | 374.7 | 323.9 | 130 | 12.7 | 31.8 | 28.6 | 450.9 | ||

| Inch | 14″ | 23 | 2.12 | 16.25 | 16.75 | 14 | 5.62 | 01/02/07 | 20 | 1.25 | 1 1/8″ | 20.25 |

| Millimeter | 584.2 | 53.8 | 412.8 | 425.5 | 355.6 | 142.7 | 12.7 | 31.8 | 28.6 | 514.4 | ||

| Inch | 16″ | 25.5 | 2.25 | 18.5 | 19 | 16 | 5.75 | 01/02/07 | 20 | 1.38 | 1 1/4″ | 22.5 |

| Millimeter | 647.7 | 57.2 | 469.9 | 482.6 | 406.4 | 146.1 | 12.7 | 35.1 | 31.8 | 571.5 | ||

| Inch | 18″ | 28 | 2.38 | 21 | 21 | 18 | 6.25 | 01/02/07 | 24 | 1.38 | 1 1/4″ | 24.75 |

| Millimeter | 711.2 | 60.5 | 533.4 | 533.4 | 457.2 | 158.8 | 12.7 | 35.1 | 31.8 | 628.7 | ||

| Inch | 20″ | 30.5 | 2.5 | 23 | 23.12 | 20 | 6.38 | 01/02/07 | 24 | 1.38 | 1 1/4″ | 27 |

| Millimeter | 774.7 | 63.5 | 584.2 | 587.2 | 508 | 162.1 | 12.7 | 35.1 | 31.8 | 685.8 | ||

| Inch | 24″ | 36 | 2.75 | 27.25 | 27.62 | 24 | 6.62 | 01/02/07 | 24 | 1.62 | 1 1/2″ | 32 |

| Millimeter | 914.4 | 69.9 | 692.2 | 701.5 | 609.6 | 168.1 | 12.7 | 41.1 | 38.1 | 812.8 |

ANSI B16.5 Class 300 Orifice Raised Flange Dimensions

| Size in In. | Size in Millimeter | Outer Diameter | Flanges Thickness | Hub OD | Weld Neck OD | WN Lengtd | RF Dia. | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Lengtd | Hole Size | ISO Stud Size | Weight in kg |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 125 | 36.6 | 54 | 33.4 | 81 | 50.8 | 2 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 4.5 |

| 1 1/2 | 40 | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 2 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 6.5 |

| 2 | 50 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 2 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 7 |

| 2 1/2 | 65 | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 2 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 7.5 |

| 3 | 80 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 2 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 9.4 |

| 4 | 100 | 255 | 36.6 | 146 | 114.3 | 90 | 157.2 | 2 | 200 | 12.7 | 8 | 3/4 | 135 | 7/8 | M20 | 13.2 |

| 6 | 150 | 320 | 36.6 | 206 | 168.3 | 98 | 215.9 | 2 | 269.9 | 12.7 | 12 | 3/4 | 135 | 7/8 | M20 | 14.6 |

| 8 | 200 | 380 | 39.7 | 260 | 219.1 | 110 | 269.9 | 2 | 330.2 | 12.7 | 12 | 7/8 | 145 | 1 | M24 | 30 |

| 10 | 250 | 445 | 46.1 | 321 | 273 | 116 | 323.8 | 2 | 387.3 | 12.7 | 16 | 1 | 165 | 1 1/8 | M27 | 41 |

| 12 | 300 | 520 | 49.3 | 375 | 323.8 | 129 | 381 | 2 | 450.8 | 12.7 | 16 | 1 1/8 | 180 | 1 1/4 | M30 | 62 |

| 14 | 350 | 585 | 52.4 | 425 | 355.6 | 141 | 412.8 | 2 | 514.4 | 12.7 | 20 | 1 1/8 | 185 | 1 1/4 | M30 | 84 |

| 16 | 400 | 650 | 55.6 | 483 | 406.4 | 144 | 469.9 | 2 | 571.5 | 12.7 | 20 | 1 1/4 | 195 | 1 3/8 | M33 | 111 |

| 18 | 450 | 710 | 58.8 | 533 | 457 | 157 | 533.4 | 2 | 628.6 | 12.7 | 24 | 1 1/4 | 205 | 1 3/8 | M33 | 138 |

| 20 | 500 | 775 | 62 | 587 | 508 | 160 | 584.2 | 2 | 685.8 | 12.7 | 24 | 1 1/4 | 215 | 1 3/8 | M33 | 171 |

| 24 | 600 | 915 | 68.3 | 702 | 610 | 167 | 692.2 | 2 | 812.8 | 12.7 | 24 | 1 1/2 | 240 | 1 5/8 | M39 | 247 |

ANSI B16.5 Class 600 Orifice Plate Flange Dimensions

| Size in In. | Size in Millimeter | Outer Diameter | Flanges Thickness | Hub Outer Diameter | Weld Neck OD | WN Length | RF Diameter | RF Height | PCD | Orifice Hole dia | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in Kilogram |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 125 | 36.6 | 54 | 33.5 | 81 | 50.8 | 7 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 5.5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 | 40 | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 7 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 7.8 |

| 2 | 50 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 7 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 8.3 |

| 2 1/2 | 65 | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 7 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 10.8 |

| 3 | 80 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 7 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 12.6 |

| 4 | 100 | 275 | 38.1 | 152 | 114.3 | 102 | 157.2 | 7 | 215.9 | 12.7 | 8 | 7/8 | 150 | 1 | M24 | 19 |

| 6 | 150 | 355 | 47.7 | 222 | 168.3 | 117 | 215.9 | 7 | 292.1 | 12.7 | 12 | 1 | 180 | 1 1/8 | M27 | 37 |

| 8 | 200 | 420 | 55.6 | 273 | 219.1 | 133 | 269.9 | 7 | 349.2 | 12.7 | 12 | 1 1/8 | 195 | 1 1/4 | M30 | 53 |

| 10 | 250 | 510 | 63.5 | 343 | 273 | 152 | 323.8 | 7 | 431.8 | 12.7 | 16 | 1 1/4 | 220 | 1 3/8 | M33 | 86 |

| 12 | 300 | 560 | 66.7 | 400 | 323.8 | 156 | 381 | 7 | 489 | 12.7 | 20 | 1 1/4 | 230 | 1 3/8 | M33 | 102 |

| 14 | 350 | 605 | 69.9 | 432 | 355.6 | 165 | 412.8 | 7 | 527 | 12.7 | 20 | 1 3/8 | 240 | 1 1/2 | M36 | 150 |

| 16 | 400 | 685 | 76.2 | 495 | 406.4 | 178 | 469.9 | 7 | 603.2 | 12.7 | 20 | 1 1/2 | 260 | 1 5/8 | M39 | 190 |

| 18 | 450 | 745 | 82.6 | 546 | 457.2 | 184 | 533.4 | 7 | 654 | 12.7 | 20 | 1 5/8 | 280 | 1 3/4 | M42 | 240 |

| 20 | 500 | 815 | 88.9 | 610 | 508 | 190 | 584.2 | 7 | 723.9 | 12.7 | 24 | 1 5/8 | 300 | 1 3/4 | M42 | 295 |

| 24 | 600 | 940 | 101.6 | 718 | 609.6 | 203 | 692.2 | 7 | 838.2 | 12.7 | 24 | 1 7/8 | 335 | 2 | M48 | 365 |

ANSI B16.5 Class 900 Orifice Flange Dimensions

| Size in In. | Size in Millimeter | Outer Diameter | Flanges Thickness | Hub Outer Diameter | Weld Neck Outer | WN Length | RF Diameter | RF Height | PCD | Orifice Hole dia | Number of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in Kilogram |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 150 | 38.1 | 52 | 33.5 | 83 | 50.8 | 7 | 101.6 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 5.4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 | 40 | 180 | 38.1 | 70 | 48.3 | 89 | 73 | 7 | 123.8 | 6.4 | 4 | 1 | 160 | 1 1/8 | M27 | 7.8 |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 6.4 | 8 | 7/8 | 150 | 1 | M30 | 11.5 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 6.4 | 8 | 1 | 165 | 1 1/8 | M27 | 15.8 |

| 3 | 80 | 240 | 38.1 | 127 | 88.9 | 102 | 127 | 7 | 190.5 | 9.5 | 8 | 7/8 | 150 | 1 | M24 | 22 |

| 4 | 100 | 290 | 44.5 | 159 | 114.3 | 114 | 157.2 | 7 | 235 | 12.7 | 8 | 1 1/8 | 180 | 1 1/4 | M30 | 22 |

| 6 | 150 | 380 | 55.6 | 235 | 168.3 | 140 | 215.9 | 7 | 317.5 | 12.7 | 12 | 1 1/8 | 195 | 1 1/4 | M30 | 70 |

| 8 | 200 | 470 | 63.5 | 298 | 219.1 | 162 | 269.9 | 7 | 393.7 | 12.7 | 12 | 1 3/8 | 230 | 1 1/2 | M36 | 119 |

| 10 | 250 | 545 | 69.9 | 368 | 273 | 184 | 323.8 | 7 | 469.9 | 12.7 | 16 | 1 3/8 | 240 | 1 1/2 | M36 | 204 |

| 12 | 300 | 610 | 79.4 | 419 | 323.8 | 200 | 381 | 7 | 533.4 | 12.7 | 20 | 1 3/8 | 260 | 1 1/2 | M36 | 303 |

| 14 | 350 | 640 | 85.8 | 451 | 355.6 | 213 | 412.8 | 7 | 558.8 | 12.7 | 20 | 1 1/2 | 280 | 1 5/8 | M39 | 400 |

| 16 | 400 | 705 | 88.9 | 508 | 406.4 | 216 | 469.9 | 7 | 616 | 12.7 | 20 | 1 5/8 | 290 | 1 3/4 | M42 | 510 |

| 18 | 450 | 785 | 101.9 | 565 | 457.2 | 229 | 533.4 | 7 | 685.8 | 12.7 | 20 | 1 7/8 | 330 | 2 | M48 | 738 |

| 20 | 500 | 855 | 108 | 622 | 508 | 248 | 584.2 | 7 | 749.3 | 12.7 | 20 | 2 | 355 | 2 1/8 | M52 | 932 |

| 24 | 600 | 1040 | 139.7 | 749 | 609.6 | 292 | 692.2 | 7 | 901.7 | 12.7 | 20 | 2 1/2 | 445 | 2 5/8 | M64 | 1511 |

ANSI B16.5 Class 1500 Orifice Flange Dimensions

| Size in In. | Size in Millimeter | Outer Diameter | Flanges Thickness | Hub Outer Diameter | Weld Neck Outer Diameter | WN Length | RF Diameter | RF Height | PCD | Orifice Hole dia | Number of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in Kilogram |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 150 | 38.1 | 52 | 33.5 | 83 | 50.8 | 7 | 101.6 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 5.4 |

| 1 1/2 | 40 | 180 | 38.1 | 70 | 48.3 | 89 | 73 | 7 | 123.8 | 6.4 | 4 | 1 | 160 | 1 1/8 | M27 | 7.8 |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 6.4 | 8 | 7/8 | 150 | 1 | M24 | 11.5 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 6.4 | 8 | 1 | 165 | 1 1/8 | M27 | 15.8 |

| 3 | 80 | 265 | 47.7 | 133 | 88.9 | 117 | 127 | 7 | 203.2 | 9.5 | 8 | 1 1/8 | 185 | 1 1/4 | M30 | 22 |

| 4 | 100 | 310 | 54 | 162 | 114.3 | 124 | 157.2 | 7 | 241.3 | 12.7 | 8 | 1 1/4 | 205 | 1 3/8 | M33 | 22 |

| 6 | 150 | 395 | 82.6 | 229 | 168.3 | 171 | 215.9 | 7 | 317.5 | 12.7 | 12 | 1 3/8 | 265 | 1 1/2 | M36 | 70 |

| 8 | 200 | 485 | 92.1 | 292 | 219.1 | 213 | 269.9 | 7 | 393.7 | 12.7 | 12 | 1 5/8 | 300 | 1 3/4 | M42 | 119 |

| 10 | 250 | 585 | 108 | 368 | 273 | 254 | 323.8 | 7 | 482.6 | 12.7 | 12 | 1 7/8 | 345 | 1 | M48 | 204 |

| 12 | 300 | 675 | 123.9 | 451 | 323.8 | 283 | 381 | 7 | 571.5 | 12.7 | 16 | 2 | 380 | 2 1/8 | M52 | 303 |

| 14 | 350 | 750 | 133.4 | 495 | 355.6 | 298 | 412.8 | 7 | 635 | 12.7 | 16 | 2 1/4 | 415 | 2 3/8 | M56 | 400 |

| 16 | 400 | 825 | 146.1 | 552 | 406.4 | 311 | 469.9 | 7 | 704.8 | 12.7 | 16 | 2 1/2 | 450 | 2 5/8 | M64 | 510 |

| 18 | 450 | 915 | 162 | 597 | 457.2 | 327 | 533.4 | 7 | 774.7 | 12.7 | 16 | 2 3/4 | 500 | 2 7/8 | M72 | 738 |

| 20 | 500 | 985 | 177.8 | 641 | 508 | 356 | 584.2 | 7 | 831.8 | 12.7 | 16 | 3 | 545 | 3 1/8 | M76 | 932 |

| 24 | 600 | 1170 | 203.2 | 762 | 609.6 | 406 | 692.2 | 7 | 990.6 | 12.7 | 16 | 3 1/2 | 620 | 3 5/8 | M90 | 1511 |

ANSI B16.5 Class 2500 Orifice Flange Dimensions

| Size in In. | Size in Millimeter | Outer Diameter | Flanges Thickness | Hub OD | Weld Neck OD | WN Length | RF Diameter | RF Height | PCD | Orifice Hole dia | Number of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in Kilogram |

| A | B | C | D | E | F | G | H | I | ||||||||

| 1 | 25 | 160 | 38.1 | 57 | 33.5 | 92 | 50.8 | 7 | 108 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 6.5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 | 40 | 205 | 44.5 | 79 | 48.3 | 111 | 73 | 7 | 146 | 6.4 | 4 | 1 1/8 | 180 | 1 1/4 | M30 | 13 |

| 2 | 50 | 235 | 50.8 | 95 | 60.3 | 127 | 92.1 | 7 | 171.4 | 6.4 | 8 | 1 | 185 | 1 1/8 | M27 | 19 |

| 2 1/2 | 65 | 265 | 57.2 | 114 | 73 | 143 | 104.8 | 7 | 196.8 | 6.4 | 8 | 1 1/8 | 205 | 1 1/4 | M30 | 24 |

| 3 | 80 | 305 | 66.7 | 133 | 88.9 | 168 | 127 | 7 | 228.6 | 9.5 | 8 | 1 1/4 | 230 | 1 3/8 | M33 | 43 |

| 4 | 100 | 355 | 76.2 | 165 | 114.3 | 190 | 157.2 | 7 | 273 | 12.7 | 8 | 1 1/2 | 260 | 1 5/8 | M39 | 66 |

| 6 | 150 | 485 | 108 | 235 | 168.3 | 273 | 215.9 | 7 | 368.3 | 12.7 | 8 | 2 | 350 | 2 1/8 | M52 | 172 |

| 8 | 200 | 550 | 127 | 305 | 219.1 | 318 | 269.9 | 7 | 438.2 | 12.7 | 12 | 2 | 385 | 2 1/8 | M52 | 261 |

| 10 | 250 | 675 | 165.1 | 375 | 273 | 419 | 323.8 | 7 | 539.8 | 12.7 | 12 | 2 1/2 | 490 | 2 5/8 | M64 | 485 |

| 12 | 300 | 760 | 184.2 | 441 | 323.8 | 464 | 381 | 7 | 619.1 | 12.7 | 12 | 2 3/4 | 540 | 2 7/8 | M72 | 730 |

ANSI B16.5 Orifice Flange Weights by Pressure Class and Size

| ASME B16.36 Orifice Flange Weights by Pressure Class and Size | ||||||||||||||||||

| NPS | Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 | Class 2500 | ||||||||||||

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | |

| 1/2″ | 2 | 1 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | Class 1500 Weight | 5 | 4 | 4 | 7 | 7 | 7 | ||

| 3/4″ | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | Class 1500 Weight | 6 | 5 | 6 | 8 | 8 | 8 | ||

| 1″ | 3 | 2 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | Class 1500 Weight | 9 | 8 | 8 | 12 | 11 | 11 | ||

| 1 1/2″ | 4 | 3 | 3 | 7 | 6 | 6 | 8 | 7 | 8 | Class 1500 Weight | 13 | 12 | 13 | 25 | 22 | 23 | ||

| 2″ | 6 | 5 | 5 | 9 | 7 | 8 | 12 | 9 | 10 | Class 1500 Weight | 25 | 25 | 25 | 42 | 37 | 39 | ||

| 2 1/2″ | 8 | 7 | 7 | 12 | 10 | 12 | 18 | 13 | 15 | Class 1500 Weight | 36 | 36 | 35 | 52 | 55 | 56 | ||

| 3″ | 10 | 8 | 9 | 15 | 13 | 16 | 23 | 16 | 20 | 31 | 26 | 29 | 48 | 48 | 48 | 94 | 83 | 86 |

| 4″ | 15 | 13 | 17 | 25 | 22 | 27 | 42 | 37 | 41 | 53 | 53 | 54 | 73 | 73 | 73 | 145 | 125 | 130 |

| 5″ | 19 | 15 | 20 | 32 | 28 | 35 | 68 | 63 | 68 | 86 | 83 | 87 | 130 | 130 | 140 | 245 | 210 | 225 |

| 6″ | 24 | 19 | 26 | 42 | 39 | 50 | 81 | 80 | 86 | 110 | 110 | 115 | 165 | 165 | 160 | 380 | 325 | 345 |

| 8″ | 39 | 30 | 45 | 67 | 58 | 81 | 120 | 115 | 140 | 175 | 170 | 200 | 275 | 260 | 300 | 580 | 485 | 530 |

| 10″ | 52 | 43 | 70 | 91 | 81 | 124 | 190 | 170 | 230 | 260 | 245 | 290 | 455 | 435 | 510 | 1075 | 930 | 1025 |

| 12″ | 80 | 64 | 110 | 140 | 115 | 185 | 225 | 200 | 295 | 325 | 325 | 415 | 690 | 580 | 690 | 1525 | 1100 | 1300 |

| 14″ | 110 | 90 | 140 | 180 | 165 | 250 | 280 | 230 | 355 | 400 | 400 | 520 | 940 | NA | 975 | NA | NA | NA |

| 16″ | 140 | 98 | 180 | 250 | 190 | 295 | 390 | 330 | 495 | 495 | 425 | 600 | 1250 | NA | 1300 | NA | NA | NA |

| 18″ | 150 | 130 | 220 | 320 | 250 | 395 | 475 | 400 | 630 | 680 | 600 | 850 | 1625 | NA | 1750 | NA | NA | NA |

| 20″ | 180 | 165 | 285 | 400 | 315 | 505 | 590 | 510 | 810 | 830 | 730 | 1075 | 2050 | NA | 2225 | NA | NA | NA |

| 22″ | 225 | 185 | 355 | 465 | 370 | 640 | 720 | 590 | 1000 | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 24″ | 260 | 220 | 430 | 580 | 475 | 790 | 830 | 730 | 1250 | 1500 | 1400 | 2025 | 3325 | NA | 3625 | NA | NA | NA |

B16.5 Class 1500 Blind Flange Material

| Carbon Steel ANSI B16.5 Orifice Flanges | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Stainless Steel ANSI B16.5 Orifice Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Alloy Steel ANSI B16.5 Orifice Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium ANSI B16.5 Orifice Flanges | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper ANSI B16.5 Orifice Flanges | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel ANSI B16.5 Orifice Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass ANSI B16.5 Orifice Flanges | 3602 / 2604 / H59 / H62 / etc. |

| Inconel ANSI B16.5 Orifice Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Orifice Flanges |

| Hastelloy ANSI B16.5 Orifice Flanges | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel ANSI B16.5 Orifice Flanges | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 ANSI B16.5 Orifice Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium ANSI B16.5 Orifice Flanges | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel ANSI B16.5 Orifice Flanges | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex ANSI B16.5 Orifice Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex ANSI B16.5 Orifice Flanges | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy ANSI B16.5 Orifice Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 Smo ANSI B16.5 Orifice Flanges | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic ANSI B16.5 Orifice Flanges | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other ANSI B16.5 Orifice Flanges Material | Tin bronze, Alumunum bronze, Lead bronze |

Types of ANSI B16.5 Orifice Flanges We Supply

| ANSI B16.36 300 LBS Stainless Steel 317 Orifice Flange | Industrial Orifice Flanges Manufacturer |

| ANSI B16.36 High Nickel Alloy Orifice Flanges | UNS S30400 Orifice Flanges |

| ANSI B16.36 Orifice Flanges Class 150 LBS | ANSI B16.36 Stainless Steel S31603 Orifice Flanges Dealer |

| ANSI B16.36 Titanium Grade 2 Orifice Flange | ANSI B16.36 Ti 3.7035 Orifice Flanges |

| UNS C70600 Orifice Flanges | ANSI B16.36 SS 900 LBS Orifice Flange |

| ASTM B564 Threaded Orifice Flange | ASTM B564 UNS N10665 Threaded Orifice Flange |

| Wrought Austenitic Stainless Steel Orifice Flanges | ANSI B16.36 Duplex steel 2205 Orifice Flanges |